Crafting Essence: The Art of Steam Distilling Frankincense in a Copper Alembic Still

Awaken To The OneShare

The Art and Science of Steam Distilling Frankincense in a Copper Alembic Still

Frankincense, known as Boswellia in the scientific world, has been revered for thousands of years for its aromatic resin. It has been used in religious ceremonies, traditional medicine, and perfumery, making it one of the most cherished and sought-after materials in the world of essential oils. Among the various methods used to extract essential oils, steam distillation has remained a time-honored technique. When combined with the craftsmanship of a copper alembic still, steam distillation becomes an art form, yielding one of the most pure and aromatic oils.

In this blog, we will dive deep into the process of steam distilling frankincense using a copper alembic still, exploring the history, benefits, and intricacies of the distillation process itself.

The History and Significance of Frankincense

Frankincense resin is harvested from the Boswellia tree, which grows primarily in the arid regions of the Middle East, Africa, and parts of India. Its aromatic qualities have been highly prized since ancient times. The Egyptians, Greeks, and Romans used frankincense in incense for religious rituals, while ancient healers also applied it for its medicinal properties. Today, frankincense is still widely used in aromatherapy and as an ingredient in luxury perfumes.

The resin of the Boswellia tree, which is collected by making small incisions in the bark, is the source of frankincense essential oil. When steam distilled, it yields a warm, rich, and grounding scent, with citrusy and woody notes that embody the spiritual, medicinal, and natural qualities of the resin.

Understanding Steam Distillation: The Core of Essential Oil Extraction

Steam distillation is a gentle yet effective method for extracting essential oils from plant materials, including frankincense. The process utilizes steam to separate the essential oil from the plant material, without causing any degradation to the oil. This results in a product that retains its natural, therapeutic qualities, making it suitable for both personal and professional use.

-

The Basics of Steam Distillation The steam distillation process involves the following basic steps:

- Steam generation: Water is heated to produce steam, which rises through the plant material (in this case, frankincense resin) in the distillation apparatus.

- Condensation: The steam carrying the volatile essential oils then travels through a cooling system, where it condenses back into water and essential oil.

- Separation: Once condensed, the essential oil, being less dense than water, floats on top of the distillation water. This oil is then separated and collected for use.

-

Why Steam Distillation? Steam distillation is preferred over other methods like cold pressing or solvent extraction for several reasons:

- Purity: Steam distillation is a very pure form of extraction, with minimal impact on the chemical structure of the essential oil.

- Safety: As a non-toxic method, it ensures that the essential oils remain free from harmful residues.

- Preservation of Therapeutic Properties: Steam distillation preserves the delicate compounds of the essential oil, ensuring that frankincense oil retains its grounding, soothing, and spiritually uplifting qualities.

Copper Alembic Still: The Art of Distillation

While steam distillation is the process, the choice of distillation apparatus is equally important. Copper alembic stills are the tool of choice for many professional distillers because of their centuries-old tradition and unique properties. Let's dive deeper into why a copper alembic still is the ideal vessel for steam distilling frankincense.

-

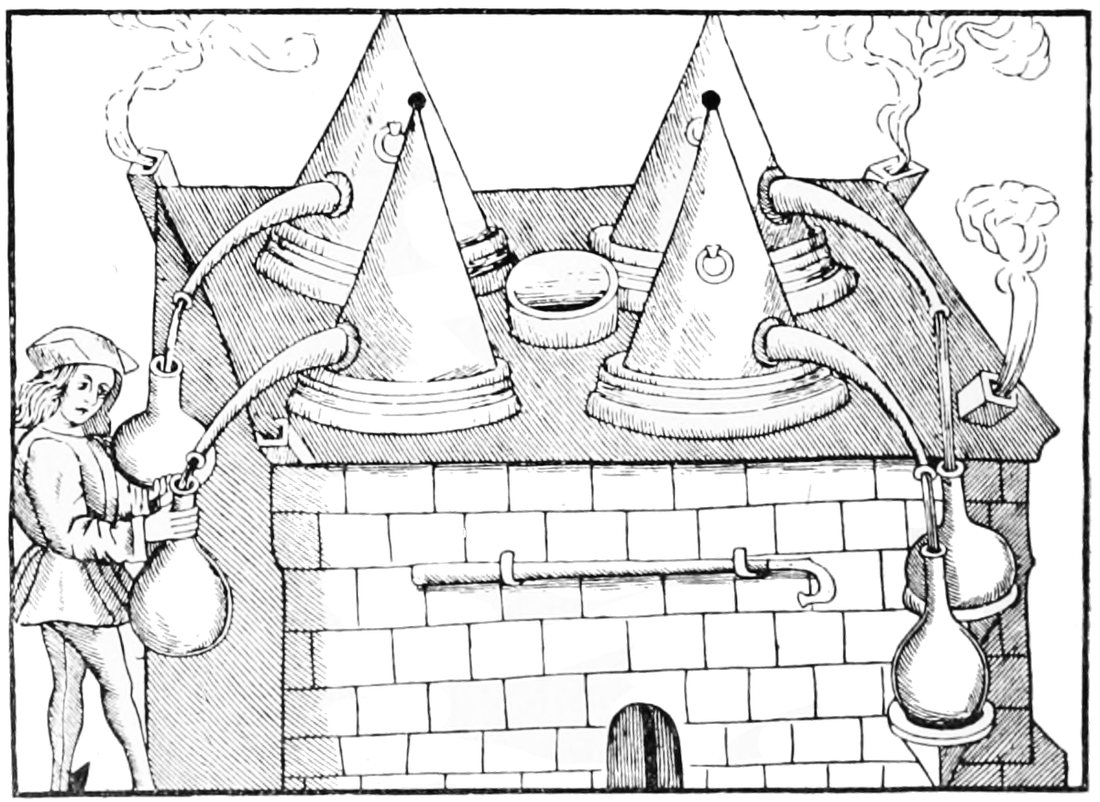

The Historical Significance of Copper Alembic Stills Copper stills date back to the early civilizations of the Middle East, where they were used for distilling perfumes, essential oils, and even alcoholic beverages like wine. The alembic still, a specific type of copper still, became synonymous with the art of distillation during the Islamic Golden Age. The alembic still is composed of two main parts: the boiler (or pot) where the plant material and water are placed, and the condensation chamber where the steam is condensed back into liquid.

-

Why Copper? Copper is preferred for distillation for several key reasons:

- Thermal Conductivity: Copper heats up quickly and evenly, which is essential for maintaining the precise temperature required for steam distillation. This ensures a consistent and controlled process, which is crucial when extracting the subtle compounds found in frankincense.

- Catalytic Properties: Copper has natural catalytic properties that can improve the distillation process by reducing unwanted chemical reactions. This helps maintain the integrity of the essential oil and results in a higher-quality product.

- Durability and Longevity: Copper is a highly durable material, meaning a well-crafted copper alembic still can last for generations. It also develops a beautiful patina over time, adding to the aesthetic appeal of the still.

-

The Unique Structure of an Alembic Still The alembic still is designed to maximize efficiency while preserving the quality of the oil. The structure of the still includes:

- The Boiler: This is where water and frankincense resin are placed. The water is heated to generate steam, which rises through the plant material and carries the essential oils.

- The Swanneck: A long, curved neck that allows the steam to rise and carry the essential oils up to the condensation chamber.

- The Condensation Chamber: Here, the steam cools and condenses back into liquid form. The essential oil floats on top of the hydrosol (distilled water), allowing it to be collected separately.

The Steam Distillation Process of Frankincense in a Copper Alembic Still

To truly appreciate the distillation process, let’s walk through the steps involved in steam distilling frankincense in a copper alembic still.

-

Preparation of Frankincense Resin Frankincense resin comes in the form of hardened droplets, which are collected from the Boswellia tree. Before distillation, the resin is typically crushed into smaller pieces to allow the steam to penetrate more easily and extract the essential oils effectively.

-

Setting Up the Alembic Still Once the frankincense is prepared, the distiller fills the boiler with the resin and adds water. The amount of water should be carefully measured to ensure that it produces enough steam without overfilling the still. The boiler is then heated to produce steam, and the condensation process begins.

-

The Distillation Process As the steam rises through the frankincense, it begins to carry the volatile compounds from the resin, including the essential oils. These compounds mix with the steam and travel up the swanneck of the alembic still, where they eventually condense into a liquid in the condenser. This liquid is a mixture of water and essential oil, known as the distillate.

-

Separation of the Essential Oil Once the distillation is complete, the distillate is allowed to cool. Since essential oils are less dense than water, they float on top of the hydrosol, a fragrant water leftover from the process. The oil is carefully separated from the water using a separator or a decanter, and it is then collected in a glass container. The essential oil is now ready for use in aromatherapy, perfumery, or other applications.

-

Post-Distillation Care After the distillation, it’s important to clean and maintain the copper alembic still to ensure its longevity. The still should be rinsed thoroughly to remove any residue, and it should be dried completely before being stored.

The Final Product: Frankincense Essential Oil

After the steam distillation process is complete, the result is a pure and potent frankincense essential oil. The scent of the oil can vary depending on factors like the region where the frankincense was harvested, the method of distillation, and the care taken during the process. However, the oil is generally characterized by its deep, woody, resinous aroma, with subtle citrus notes that evoke feelings of tranquility and grounding.

The therapeutic benefits of frankincense oil are widely acknowledged. It is known to promote relaxation, reduce stress, support immune health, and enhance meditation practices. Its calming properties also make it a popular choice in skincare formulations, where it is used for its anti-aging and skin-rejuvenating effects.

Conclusion

Steam distilling frankincense in a copper alembic still is not just a technical process—it’s a blend of art and science. By understanding and respecting the history, technique, and unique properties of the materials involved, distillers can create a product that is pure, potent, and deeply connected to centuries of tradition. Whether used for its soothing aroma in aromatherapy or as an ingredient in luxury perfumes, frankincense essential oil extracted through steam distillation offers a connection to the past while serving modern needs.

This process demonstrates the timeless bond between nature, craftsmanship, and innovation. For those who seek the finest frankincense oil, the art of distillation in a copper alembic still remains one of the best ways to capture the essence of this ancient and revered resin.